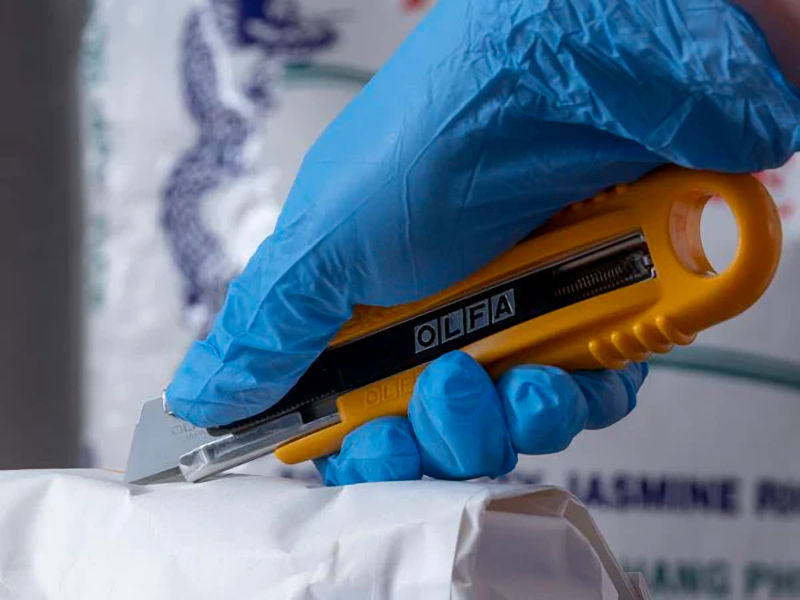

Olfa Safety Knives promote work safety

Protect your team, reduce workplace injuries, and improve cutting efficiency with OLFA Safety Knives. Designed with advanced safety features and built from high-quality materials, OLFA’s self-retracting safety knives are trusted worldwide in warehouses, retail, manufacturing, food production, and distribution facilities. Safety experts recommend OLFA because their knives are specifically engineered to reduce accidents, lower workers’ compensation claims, and improve cutting precision.

Why Choose Olfa Safety Knives?

- Self-Retracting Blade Technology – Prevents accidental injuries by automatically retracting the blade after each cut.

- Ambidextrous Use – Perfect for left- or right-handed users; simply flip the blade over.

- Durable & Long-Lasting – Built for industrial use with high-quality materials.

- Industry-Specific Options – Stainless steel NSF-certified knives like the SK-14 are designed for food production environments, resisting rust and ensuring compliance with hygiene standards.

Compared to ordinary utility knives or single-edge box cutters, OLFA safety knives like the SK-4 drastically reduce the risk of injuries while improving workflow efficiency.

OLFA’s full range of safety knives offers cutting depths and features designed for different workplace needs. The SK-4 provides a 19mm depth for general carton cutting, while the compact SK-7 offers an 11mm depth, making it lightweight and easy to handle for repetitive cuts. For added versatility, the SK-6 (10mm depth) and SK-8 (15mm depth) provide different cutting depths and ergonomic designs to reduce strain during frequent use. The SK-9, with a 19mm cutting depth, is built for heavy-duty tasks, while the SK-10 offers a shallow 4mm depth, making it ideal for cutting film, shrink wrap, or surface-level materials without damaging inner contents. For food production and hygienic environments, the SK-14 stands out with its stainless steel, NSF-certified body that resists rust and meets strict safety standards. The SK-15, with a 4mm cutting depth, is a disposable safety knife option for convenience and hygiene, while the SK-16 offers a mid-range 6.5mm depth for controlled cuts in packaging and light industrial applications. Together, OLFA Safety Knives deliver a complete solution for industries seeking safer, smarter, and more efficient alternatives to traditional box cutters.

| Part Number | Description | Order Online |

|---|---|---|

| 9048 | Olfa SK-4 | |

| 1060595 | Olfa SK-6 | |

| 1077174 | Olfa SK-7 | |

| 1077171 | Olfa SK-8 | |

| 1086095 | Olfa SK-9 | |

| 1096854 | Olfa SK-10 | |

| 1134049 | Olfa SK-14 | |

| 1136359 | Olfa SK-15 | |

| 1140922 | Olfa SK-16 |

Industries That Trust OLFA Safety Knives

- Warehouses & Distribution Centers – Minimize box cutter injuries.

- Retail Operations – Keep staff safe while stocking shelves.

- Manufacturing & Assembly – Efficiently cut packaging and materials.

- Food Production & Processing – NSF-certified stainless steel models for hygienic environments.

- Logistics & Shipping – Reliable cutting tools for fast-paced operations.

The Olfa SK-14 is a unique safety knife vital to food production. Its most interesting feature is its metal-detectable body, made from a special polymer that can be found by factory metal detectors if it accidentally breaks or falls into food. This prevents contamination and costly recalls. The knife also has an auto-retracting blade and a blunt tip, significantly reducing the risk of cuts and punctures. Easy to clean and sanitize, the SK-14 is a simple tool that plays a big part in ensuring food safety from the factory to the consumer.

The OLFA SK4 Safety Knife accepts three types of blades

- Standard dual edge blade (SKB2)—Use for cutting corrugated cartons where the potential for inner content damage is minimal.

- Rounded tip blade (RSKB)—Use to open cartons where inner contents might be easily damaged by a sharp tip.

- Hook blade (HOB2)—Use to safely slice through stretch or shrink film, string, rope or nylon banding.

See what safety professionals are saying about Olfa Safety knives

OLFA APPROVED: SAFE WAREHOUSE CUTTING TECHNIQUES

- PROPER POSITION. Position the carton so it’s a safe distance from your abdomen, hips and thighs. Then draw the knife away from your body. Always maintain a safe distance from co-workers and customers as you cut.

- SHARP IS SAFE. A dull blade requires additional pressure to make the cut or may tear the cardboard. Stop and change the blade when needed. A dull blade cuts erratically and can easily slip off the cutting path, increasing chances for injury.

- VISUAL GUIDANCE. Never use your thumb as a guide to position the blade. Instead, plan your cut visually and grasp the knife with your entire hand.

- CUT AWAY FOR HANDS. Hold the carton with your hand on the opposite side you’re cutting. Keep your hands and fingers away from the cutting area at all times.

- PROPER EXCHANGE. Never toss or hand a knife to co-worker. Set it down and let the co-worker pick it up.

- BLADE DISPOSAL. Discard used blades in a safe blade storage receptacle. Never toss in the garbage where they might injure an unsuspecting person.

- SAFETY DROPS. If you drop a knife, don’t try to catch it. Let it fall to the floor. Then examine the blade and mechanism for possible damage before using it again.

- STRETCH FILM DIRECTION. Pull stretch film away from the pallet contents before starting the cut. Start cutting the film from the top of the pallet. Never slice stretch film from the bottom up.

Across Canada and USA

Toll Free: 1-877-877-0873

Email us at sales@olfablades.ca